Students take a number of project-based design courses throughout the program as well as work on projects within other courses. Projects based on manufacturing processes (i.e. making things), automation (robotics), instrumentation (sensors), artificial intelligence and machine learning, programming/coding, production planning, and project management are typical examples.

Previous Projects

Innovative lightweight, abrasion-resistant shin pads

ALUULA Composites, a renowned high-performance material manufacturing company, specializes in creating composites with exceptional tear and stretch resistance, widely utilized across various markets.

The focus of this project was to design a cutting-edge prototype and propose a comprehensive manufacturing plan for a commercially viable product crafted from recycled remnants of ALUULA’s Aeris product line. The innovative outcome resulted in the development of soccer shin pads boasting lightweight, abrasion-resistant, and stiff characteristics – attributes highly sought after in premium shin protection gear.

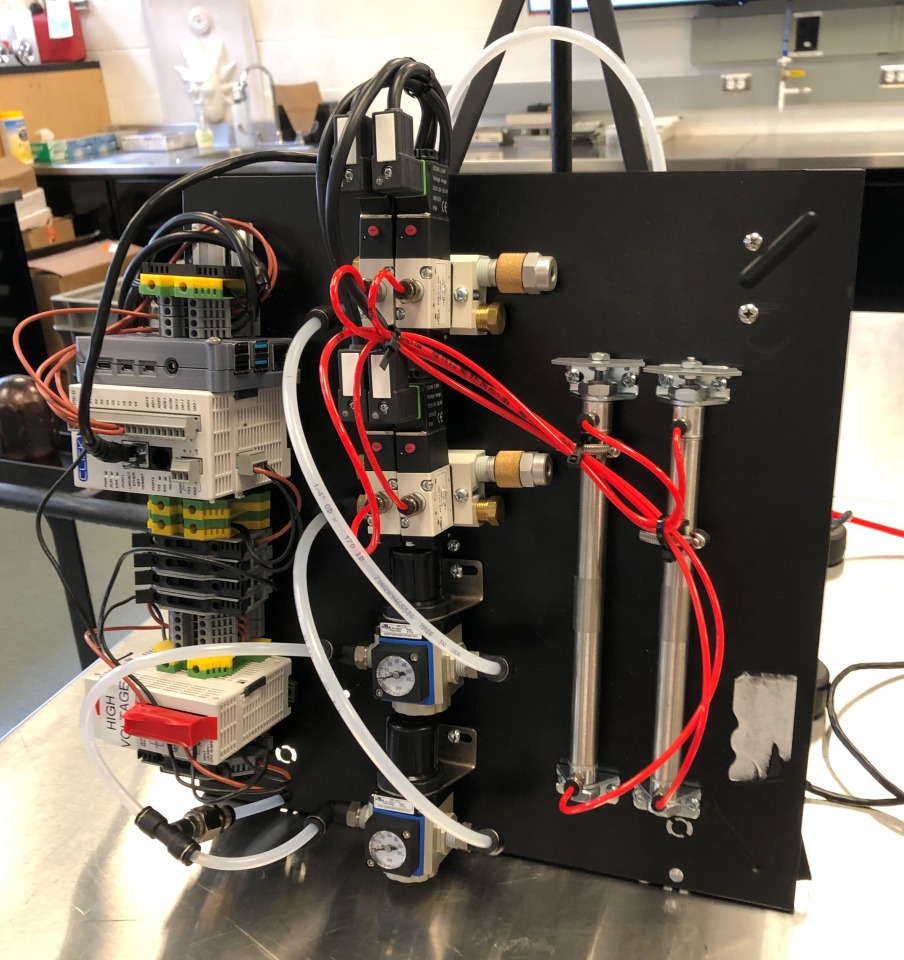

Automation of a Thermal Compound Press

Corvus Energy is the manufacturer of Energy Storage Systems (ESSs), focusing on the maritime industry.

This project designed, built, and proposed an automated pneumatic press station which would sit at Corvus’s main manufacturing line in Richmond, British Columbia, Canada. The system was designed to address all of the client’s needs and wants in regard to the automatic processing of the battery modules. Previously, the manually operated press station was labour, time, and resource intensive. The automated system freed time and resources for the organization which could be allocated to more crucial tasks.

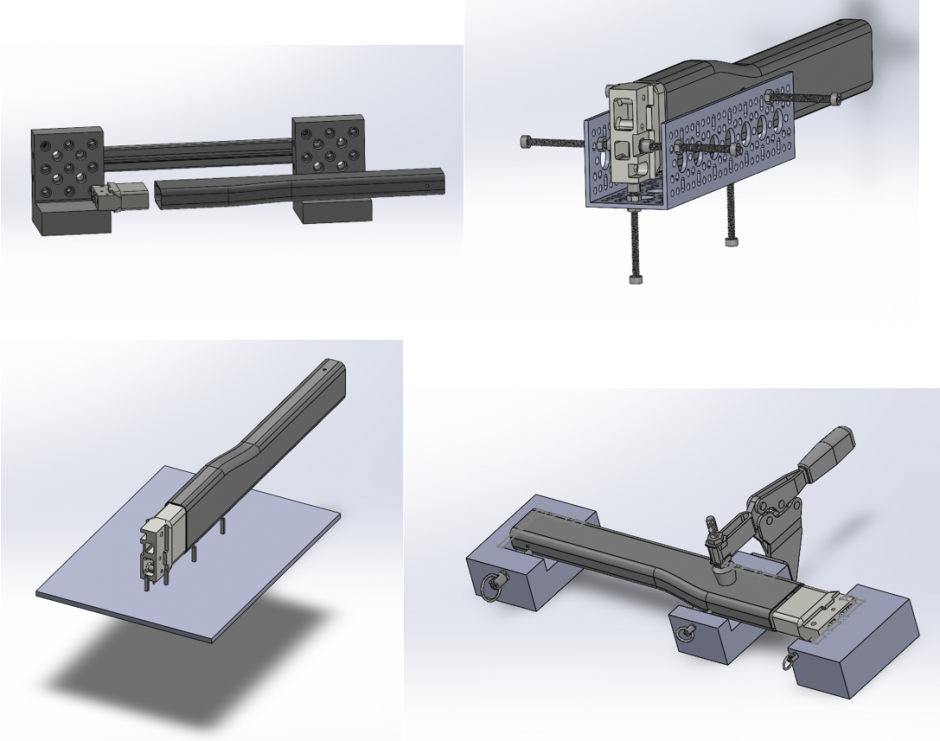

Carbon Fiber Mating Optimization

Glüxkind Technologies Inc. designs advanced AI-powered strollers to enable all parents and their babies to navigate the world safely and comfortably.

The project proposes a solution for bonding the Nylon 12 and carbon fibre composites piece together to make a robust joint to be used in the stroller. Mainly, acrylic adhesives were used as a pure adhesive, a jig was designed to aid the curing process of the joint and finally temperature and physical property tests were performed to validate the hypothesis.